|

APPLICATION

Direct measurement of current in High Voltage System

is Not possible because of insulation problem of

measuring instruments. It is also not possible to

use current flowing through the system directly for

protection purpose due to its high insulation

problem.

BASIC

FUNCTIONS OF CURRENT TRANSFORMERS ARE :

|

|

1. To reduce the line current to a value which is

suitable for standard measuring

instruments relays

etc.

2. To isolate the measuring instruments, meters, relays

etc. from high voltage

side an installation.

3.

To protect measuring instruments against short circuit currents.

4. To sense abnormalities in current and give current signals to protective relays

to isolate the defective system. |

There are four main factors which

determine the capability of current

transformer i.e.

* Insulation Level (Service

Voltage)

* Rated primary current

* Short time withstand current

* Burden and Accuracy

THE CURRENT TRANSFORMERS MUST :

1. Withstand operational voltage and over voltage in

the network

2. Withstand rated primary current in continuous

operation without exceeding

maximum allowed temperature rise.

3. Be capable o sustain thermal and mechanical

stresses developed due to

system falut current

4. Feed current to external circuit with specified

accuracy at specified primary

currents

|

|

|

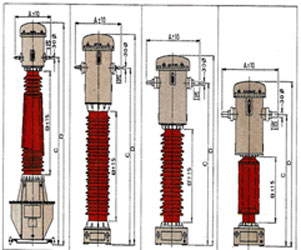

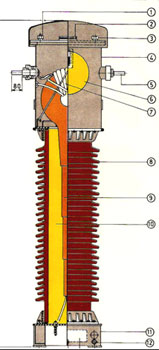

CONSTRUCTION :

Core & Secondary Winding,

Primary Winding,

Insulation,

Procelain Insulators,

Tanks & Bases,

Testing,

Packaging & Transportation,

Maintenance |

HOW TO SELECT THE

C.T.

It is impotant to specify correct

parameters of CT while ordering for optimum

design. Following are main factors for selecting

current transformer.

1. SERVICE VOLTAGE : System voltage in which CT is

to be installed e.g.

11kV, 22kV, 33kV ETC.

2. INSTALLATION : Whether OUTDOOR or INDOOR

3. ATMOSPHERIC CONDITIONS : Such as condition of

Pollution, Altitude

Ambient Temperature etc.

4. INSULATION LEVEL : If insulation level other than

associated with service

voltage is required, it should be

specifically mentioned.

5. RATED PRIMARY CURRENT : Specify rated primary

current / currents (if

required more than one value).

Also indicate if different primary current

is required for different cores.

6. CONTINUOUS PRIMARY CURRENT : Max.primary current

that can be withstood

continuously by current

transformer e.g. 120% of primary current

7. RATED SECONDARY CURRENT : Whether 1 Amp. or 5

Amps.

8. SHORT TIME CURRENT & ITS DURATION : Specify

fault current of the system

in which CT is to be installed

along with its duration. it is most important to

specify realistic value of S.T.C.

as at lower primary current, higher S.T.C.

value neceesitates bulky &

costlier design. Also specify dynamic current if

other than 2.5 times S.T.C. is

required.

9. NO.OF CORES THEIR BURDENS, ACCURACY : Basis of

application, No.of cores,

their burdens and accuracy class

should be specified. It is advisable to specify

minimum required Burden for

metering core as unnecessary high burden will

necessitate bulky and costlier

design. Specified accuracy is guaranteed for

100 %

to 25% of rated burden only. Current transformer offers minimum error

if 75% to 60% burden is connected to secondary, Therefore,

ideally rated

burden higher than 1.5 time actual burden should be

specified. Also, it is

important to specify correct burden in context

of instrument Security Factor

(I.S.F.). The I.S.F. indicates the over

current as multiple of rated current at

which the metering core will

saturate, thus limiting the secondary current

flowing through meter

and protect it from damage. If actual burden connected

is half of the

rated burden, the I.S.F. will increase two-fold of its rated value.

10. KNEE

POINT VOLTAGE, SECONDARY RESISTANCE AND

EXCITATION CURRENT : For

differential protection, R.E.F. Protection, Bus Bar

Protection, C.T. with

accuracy class PS is required. The Knee Point

Voltage,

Secondary resistance and

excitation current should be for this core. It is

always better to specify

Formula for Knee Point Voltage related to relay used

for the protection. This

will help designer to optimise the design.

|